Unveiling The World Of Lean Manufacturing: Remarkable Principles, Evolution, And Advancements

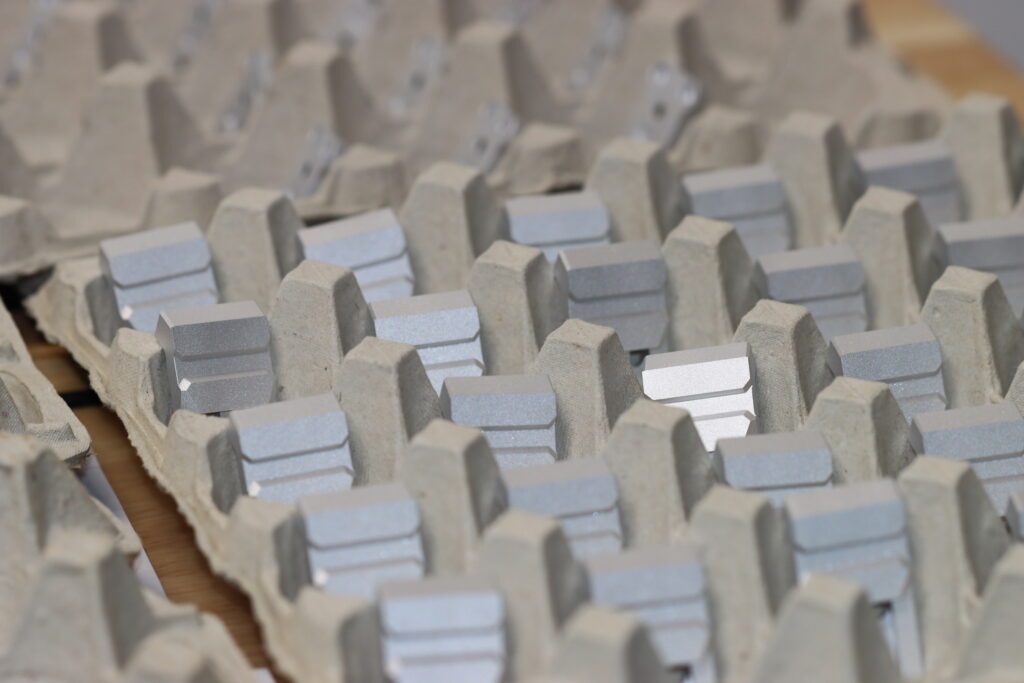

Introduction: Lean manufacturing, a philosophy rooted in efficiency and waste reduction, has revolutionized the way industries approach production processes. This article delves into the primary principles of lean manufacturing, tracing its evolution from its inception to modern-day advancements. OuterImpact uses lean manufacturing to produce the finest firearm and motorsport accessories.

| Principle | Description |

| Value Stream Mapping (VSM) | Visual mapping of the production process to identify waste and inefficiencies. |

| Just-in-Time (JIT) | Producing goods only as needed to minimize inventory costs and waste. |

| Kaizen | Continuous improvement involving all employees in incremental changes. |

| Jidoka (Autonomation) | Building quality into the production process by stopping the line when abnormalities occur. |

| Respect for People | Empowering and respecting employees, recognizing their expertise and involvement in improvement processes. |

History and Evolution of Lean Manufacturing: Lean manufacturing finds its origins in the Toyota Production System (TPS), developed by Toyota in the aftermath of World War II. Taiichi Ohno, often regarded as the father of TPS, introduced concepts such as Just-in-Time (JIT) production and Kanban systems to minimize waste and maximize efficiency.

Key Principles of Lean Manufacturing:

- Value Stream Mapping (VSM): VSM involves visually mapping out every step in the production process to identify areas of waste and inefficiency.

- Just-in-Time (JIT) Production: JIT aims to produce goods only as needed, minimizing inventory holding costs and reducing waste.

- Kaizen: Kaizen emphasizes continuous improvement, involving all employees in the process of identifying and implementing small, incremental changes.

- Jidoka (Autonomation): Jidoka refers to building quality into the production process by stopping the line when abnormalities occur, preventing defective products from being produced.

- Respect for People: Lean manufacturing places a strong emphasis on empowering and respecting employees, recognizing their expertise and involvement in the improvement process.

Advancements in Lean Manufacturing: Over the years, lean manufacturing has evolved with advancements in technology and management practices. Some notable advancements include:

- Lean Six Sigma: Integration of Six Sigma principles with lean methodologies to achieve both efficiency and quality improvements.

- Lean Management: Application of lean principles beyond the shop floor to areas such as administration, sales, and customer service.

- Industry 4.0 Integration: Utilization of technologies such as IoT, AI, and data analytics to enhance visibility, flexibility, and efficiency in lean production systems.

- Lean Supply Chain Management: Extending lean principles to the entire supply chain to optimize inventory levels, reduce lead times, and improve overall efficiency.

Development of New Techniques: The evolution of lean manufacturing has led to the development of new techniques and tools to address emerging challenges. These include:

- Total Productive Maintenance (TPM): Focuses on maximizing equipment effectiveness through proactive maintenance and employee involvement.

- Andon Systems: Visual management tools that signal abnormalities in the production process, enabling quick response and problem-solving.

- Heijunka (Production Leveling): Balances production to match customer demand, reducing variability and improving flow.

- Poka-Yoke (Error Proofing): Designing processes and systems to prevent errors before they occur, enhancing quality and efficiency.

Conclusion: From its humble beginnings in post-war Japan to its widespread adoption across industries worldwide, lean manufacturing continues to evolve and adapt to meet the challenges of modern production environments. By adhering to its core principles and embracing advancements in technology and management practices, organizations can streamline their operations, reduce waste, and enhance competitiveness in today’s dynamic marketplace. You can read more about our innovations here.